The handbrake is used to secure the vehicle when parking and to prevent movement of the car when in neutral. In addition, it is used in motorsport to put the car into a slide, or effective turns that every fan loves.

Serial cable brakes are connected to a separate or simultaneous braking system of jaws or brake shoes, which is responsible for braking the vehicle when the lever, i.e. the handbrake, is pulled. In newer vehicles, we can also find electronic hand brakes, which, after pressing a button, send a signal to the rear electric motors on the calipers, which stop the vehicle and put it in "parking" mode. This system is only used for parking and therefore it is not possible to fully brake the rear wheels at higher speeds.

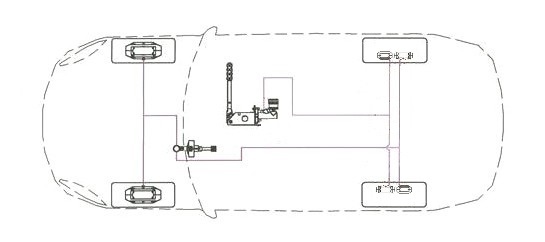

The most effective way to ensure that the rear wheels are completely locked at any speed is to install a hydraulic handbrake. It is a lever or handle that controls the hydraulic brake cylinder. The cylinder compresses the fluid in the system, which causes the rear axle to brake, just like when you press the brake pedal on the front axle. We know several ways in which the hydraulic handbrake is connected:

- in the original braking circuit

- separate (standalone) circuit

Installation and tips:

The first thing to consider is where the handbrake will be installed. This matter is subjective, but nowadays it is usual to install the handbrake in a stock position (mostly if it is a horizontal one) or between the steering wheel and the gear lever (especially during drifts) so that it is within reach of the driver (in the case of a vertical one). Brakes are also available that retain the function of the parking brake and can therefore be locked against the movement of the vehicle. However, we are also faced with the possibility of keeping the original handbrake and installing a hydraulic one (if the vehicle uses brake shoes). Installation is also facilitated by reverse hand brakes, which have the hydraulic cylinder positioned in the opposite direction (toward the engine).

The connection can be made by connecting to a serial brake system or by creating a separate circuit.

If it is a connection to the original brake system, the handbrake is installed on the output for the rear brakes either by connecting directly to the main brake cylinder or by connecting to the pipe leading to the rear brakes even before the T-section into separate rear brakes.

- Advantages: easier installation, no second pair of brake calipers required

- Disadvantages: transmission of the change in handbrake pressure when the brake is applied, worse footbrake metering when the handbrake is applied

If the manual is installed in its own circuit, it is usually necessary to install a second pair of brake calipers on the given axle, which will work regardless of the brake pedal and will be controlled only by a separate hydraulic handbrake. In this case, the handbrake needs its own brake fluid reservoir.

- Advantages: applying the handbrake does not affect the use of the footbrake, no need to interfere with the original brake system

- Disadvantages: the need to install a separate set of calipers on the rear axle, the brake fluid container in the interior of the vehicle

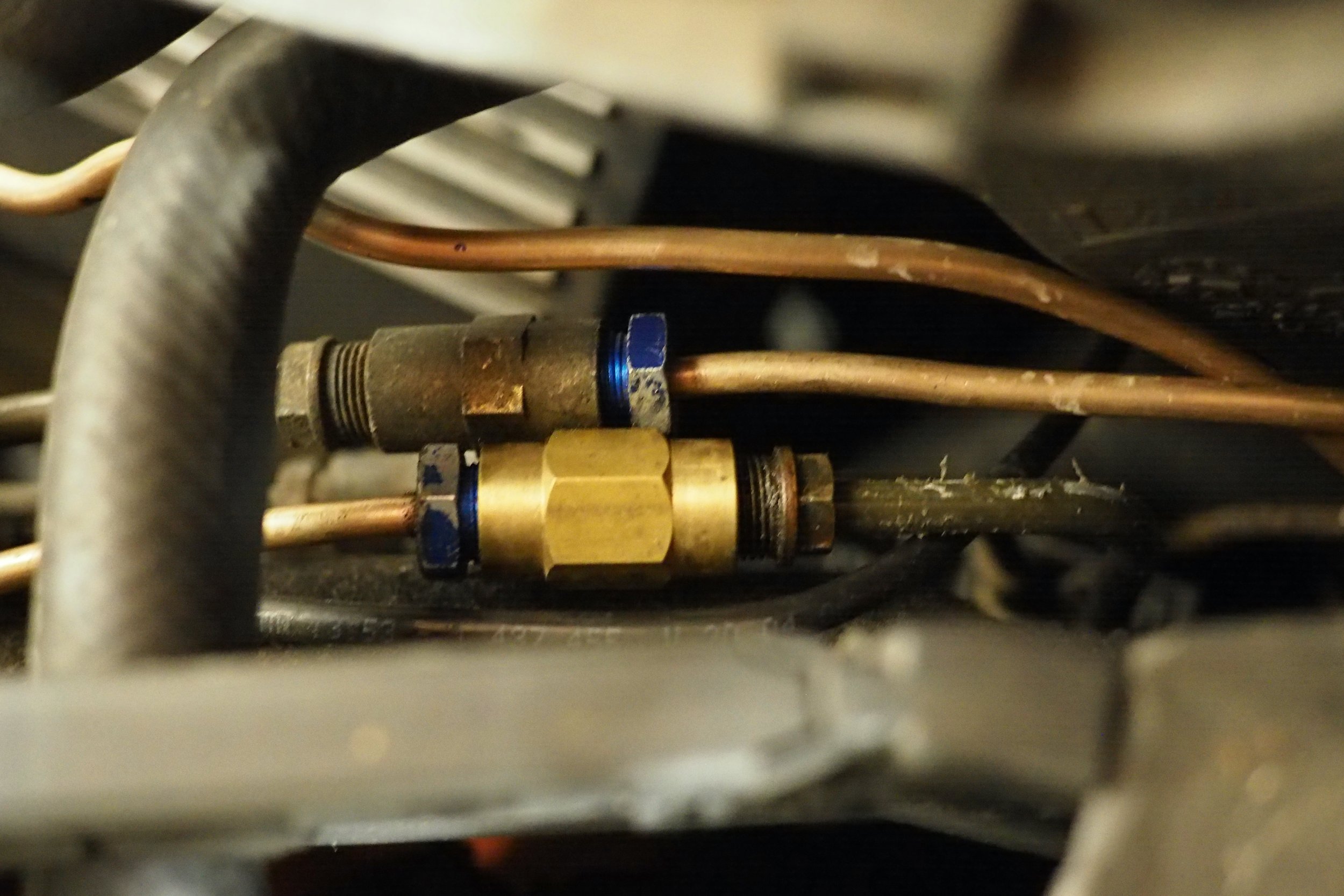

We implement the installation using copper / steel pipes or teflon hoses and fittings.

By using copper pipes, it is possible to simply guide the system in the original locations and by bending it to create the connection of the handbrake. It is a direct replacement of the original pipes, with the necessity of creating a landing surface for the brake end caps using a pipe flaring kit.

- Advantages: durable replacement for the original pipe, easy handling by bending, resistance to corrosion (in the case of copper pipes), low price

- Disadvantages: the need to create a landing surface, oxidation

The use of teflon hoses is the best connection method. Teflon hoses with stainless steel braid ensure maximum protection against environmental influences, prevent inflation (as in the case of rubber hoses) and resist racing brake fluids. Hoses are connected by stainless steel fittings in various angles and shapes, which simplifies installation.

- Advantages: maximum resistance and strength, easy installation, different colors of braid protection, fittings made of stainless steel

- Disadvantages: high price, smaller bending radius (due to the strength of the stainless steel braid)

You can find more information about Teflon brake hoses in our previous BLOG.

PRO TIP: Most hydraulic brake cylinders (such as RACES, WILWOOD, OBP,..) use an inlet thread AN4 (7/16-20) and an outlet thread AN3 (3/8-24).

PRO TIP 2: We know from our own experience that the ideal brake cylinder in most applications is 15,8mm (0,625").

In conclusion, for proper functionality, it is necessary to thoroughly vent the brake system after installation and do not forget about new brake rotors, brake pads and the correct brake fluid.

Do you have any questions? Do not hesitate to contact us.