PROFI CONSULTING

from 9am to 5pm

No products

*158 884

Price per 1 psc.

Required/car: 2

New product

PFF19-1802G_4

5055676538024

Powerflex Front Wishbone Rear Bush Anti-Lift & Caster Offset Ford Focus Mk3 inc ST and RS (2011 on)

Price per 1 psc.

Required/car: 2

Pošlite obsluhe obchodu otázku k tomuto produktu.

* povinný údaj

alebo Zrušiť

Powerflex Front Wishbone Rear Bush Anti-Lift & Caster Offset Ford Focus Mk3 inc ST and RS (2011 on)

To be informed about product update via email, fill out the form.

* Required

or Cancel

Price per 1 psc.

Required/car: 2

Diagram Reference: 2

Bush Size: -

Products Notes: PFF19-1802G is a CNC machined aluminium mount and polyurethane bush to provide 1 degree of positive caster offset and 7.5mm anti-lift properties. Focus ST and RS owners are all too familiar with the commonly reported torque steer effect of their vehicles. Our new part provides anti-lift and caster offset to improve handling characteristics and has been proven and tested on road and track.PFF19-1802Gadds 1 degree of caster offset for a greater tyre contact area, which, in turn, provides greater feedback information to the driver, improves traction and offers greater stability. The increased caster angle produces more weight and detail to the steering which is vital to driver confidence, allowing your Focus to corner with more urgency, significantly improved grip and reduced understeer.Starting out as a 6082 T6 (heat treated) solid billet of aluminium, our CNC machining centre and 4th axis shape the material into our unique design which is then hard black anodized, followed by an engraving process. By machining from a solid billet, we ensure our part has the best strength to weight ratio and looks great too. PFF19-1802G ships with CNC machined stainless steel-steel thrust washers to enhance braking stability.In our Purple Shore 80A Road Series material, PFF19-1802G is 10% stiffer than the original rubber bush, whilst our Black Series Shore 95A material is 85% stiffer than the original for those looking for a Track/Competition option.

Weight: 159.95g

OEM: F1F1-3A423-AAA / F1F1-3A-3A424-BAA F1F1-3A423-AAA / F1F1-3A-3A424-BAA F1F1-3A-423-AAB / F1F1-3A-424-AAB

Application:

Ford C-Max MK2 (2011 ON)

Ford Focus Mk3 inc ST and RS (2011 on)

Ford Focus Mk3 inc ST and RS (2011 on)

Ford Focus Mk3 inc ST and RS (2011 on)

Ford Transit Connect MK2 - (2013 -)

Mazda Mazda 3 Mazda 3 BL (2009-2013)

Powerflex was formed in 1996 in UK to take advantage of the significant advances made in the development of polyurethane in recent years. The company has wide experience of automotive suspension and chassis systems and combining these design skills with advanced polyurethane manufacturing techniques led to the development of the wide range of high performance automotive polyurethane components now known the world over by the product name POWERFLEX.

Component manufacturing is carried out with the latest automatic processing equipment ensuring 100% right first time quality.

Testing of new components is carried out both on the vehicle and on test rigs. POWERFLEX were selected to receive a Queen’s Award for Enterprise International Trade 2013 and in December 2014 certified to ISO 9001 as a manufacturer underlining their quality and stature as a global exporter.

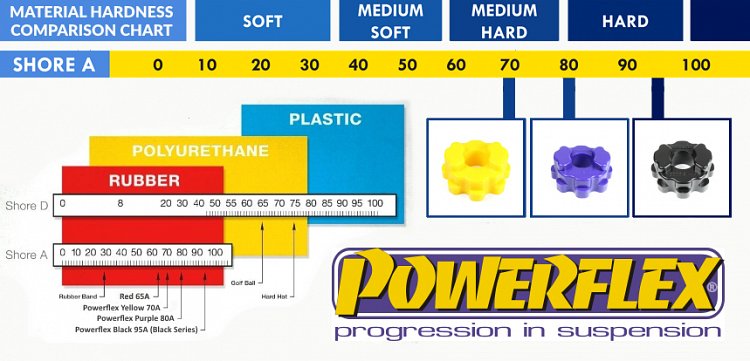

Materials are colour coded to make them easily identifiable. Below explains the shore rating and their common uses.

| Location | Front |

| Diagram reference number | 2 |

| Type | Street |

This discussion is especially meant for information exchange between customers. For questions regarding your order or stock availability, please contact us directly.

Price per 1 psc.Required/car: 2