PROFI CONSULTING

from 9am to 5pm

No products

*78 765

Price per 1 psc.

Required/car: 2

New product

PFF1-802BLK_4

5055676512789

Powerflex Front Lower Wishbone Rear Bush Fiat Tipo (1988-1995)

Price per 1 psc.

Required/car: 2

Pošlite obsluhe obchodu otázku k tomuto produktu.

* povinný údaj

alebo Zrušiť

Powerflex Front Lower Wishbone Rear Bush Fiat Tipo (1988-1995)

To be informed about product update via email, fill out the form.

* Required

or Cancel

Price per 1 psc.

Required/car: 2

Diagram Reference: 2

Bush Size: N/A

Products Notes: These bushes are designed to fit genuine control arms. If non genuine arms are fitted and you find the stainless steel sleeve not to fit onto the wishbone, please contact us with dimensions of the wishbone pin as you will require modified sleeves. PFF1-802 kit comes with different sized rings. Please select the correct ring depending on the rear bracket fitted.Use the smaller ring (802b) with the aluminium bracket and 802c with the pressed steel bracket.It is only possible to fit these bushes after removing the arms from the car.For arms fitted with the pressed steel rear bracket, the rubber bush may need to beburned out using a blowtorch, firstly and then the bracket cleaned thoroughly to ensure a good surface.WE RECOMMEND THE USE OF LOCTITE 648 OR 848 TO SECURE CENTRE SLEEVE TO ARM

Weight: 639g

OEM: N/A

Application:

Alfa Romeo 145, 146, 155 (1992-2000)

Alfa Romeo GTV & Spider 2.0 & V6, 916 (1995-2005)

Fiat Coupe (1993-2000), Brava, Bravo, Marea (1995-2001)

Fiat Tipo (1988-1995)

Lancia Delta Gen 1&2 (1983-2000), Dedra (1989-2000)

Powerflex was formed in 1996 in UK to take advantage of the significant advances made in the development of polyurethane in recent years. The company has wide experience of automotive suspension and chassis systems and combining these design skills with advanced polyurethane manufacturing techniques led to the development of the wide range of high performance automotive polyurethane components now known the world over by the product name POWERFLEX.

Component manufacturing is carried out with the latest automatic processing equipment ensuring 100% right first time quality.

Testing of new components is carried out both on the vehicle and on test rigs. POWERFLEX were selected to receive a Queen’s Award for Enterprise International Trade 2013 and in December 2014 certified to ISO 9001 as a manufacturer underlining their quality and stature as a global exporter.

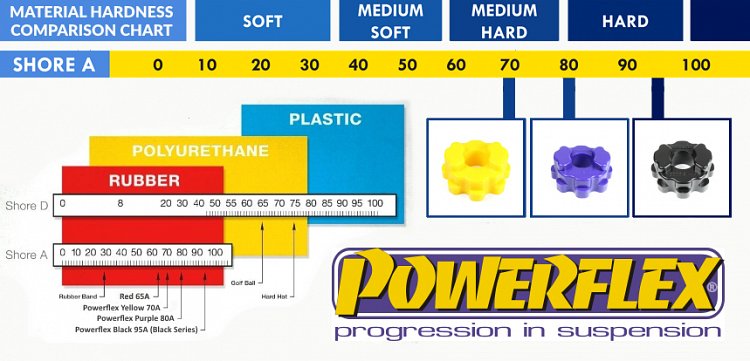

Materials are colour coded to make them easily identifiable. Below explains the shore rating and their common uses.

| Diagram reference number | 2 |

| Location | Front |

| Type | Racing |

This discussion is especially meant for information exchange between customers. For questions regarding your order or stock availability, please contact us directly.

Price per 1 psc.Required/car: 2